在 Centry,我们渴望成为工程师和买家的首选来源,提供电子设计、原型设计、测试和制造服务。请参阅我们的质量政策、质量手册和证书。我们对客户满意度、订单精确度和准时交货的承诺定义了我们卓越的客户服务。

我们84%的供应商直接来自原始制造商或信誉良好的全球分销商,而16%的供应商是从经过验证的正宗OEM或库存商中精心挑选的。

我们所有的货物都完全可追溯到其来源和各自的制造商,确保透明度和真实性

我们的内部实验室配备了全面的测试仪器,确保严格的质量控制措施

我们不断完善我们的程序以超越客户的要求,提供满足所有规格并在整个生命周期中证明可靠性的产品

盛世纪 与 White Horse Laboratories 和 CECC Laboratories合作,恪守全球采购和供应链管理承诺。我们的测试、检验和包装部门是为了应对不合格和假冒电子产品的泛滥而建立的。

我们在发货前提供几乎所有组件的测试报告和产品质量验证。我们广泛的内部实验室网络已通过第三方认证,可确保进行全面可靠的测试,从而最大限度地降低客户的风险。

我们提供全面的电子元件检测服务,对检测假冒元件至关重要。大多数部件都经过严格测试,以防止任何有缺陷或假冒的产品进入市场。

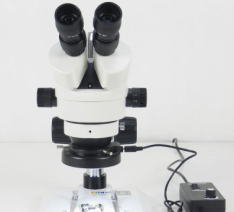

高分辨率显微镜:提供高放大倍率、清晰度,并检查组件的微观结构、标记和表面细节。能够观察表面状况和微观结构特征.

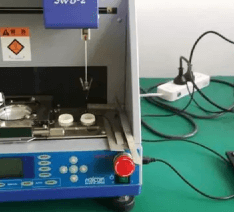

可焊性测试仪:通过检查元件在创建焊点时的可靠性来评估其焊接能力。确保附着力和可靠性,优化焊接性能和耐久性。

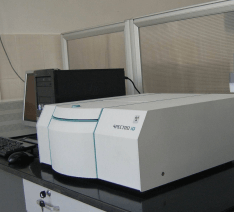

XRF 光谱仪:该设备检测材料内的元素成分,分析成分的化学组成,以确认材料的真实性和合规性.

X射线透射设备:该设备使用X射线检查组件的内部结构,以识别组件内部结构中隐藏的不规则或变化.

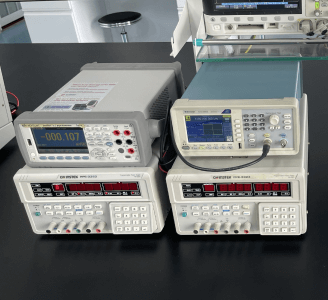

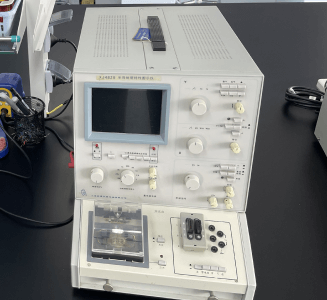

关键功能测试:测试重要的电子元件参数,如电压、电流、功率、时序、频率、相位、噪声和失真。为工程师提供准确的数据来评估是否符合设计规范.

电性能测试仪:测试电阻、电容、电感、电导率、击穿电压、噪声、失真等电性能参数。为工程师提供精确的数据来评估是否符合设计要求.

激光开封机:使用激光束非破坏性地打开电子元件封装。便于内部检查、维护和返工,且不会造成损坏.

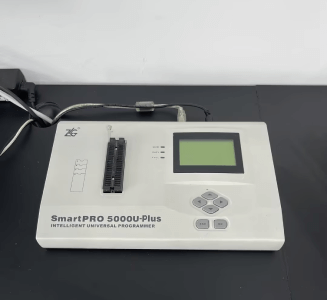

编程烧录设备:使用编程电路将程序或数据写入电子元件存储器。协助编程、烧录和测试组件。

确保组件外观完美无缺、无损坏或异常.

确认认证文件的合规性和有效性

验证组件可追溯到原始制造商.

利用X射线等无损检测方法检查内部结构

分析组件内的材料以确保它们符合规格

评估组件的功能性能以满足标准.

评估不同温度和湿度下的性能和耐腐蚀性

验证组件上标签的准确性和合规性

确保认证文件的完整性并评估包装条件

深入检查部件的外观,重点关注细微缺陷.

通过解封装和芯片评估来评估芯片完整性。

提供详细的报告,总结所有测试结果和发现。

01

01

02

02

03

03